ITW is committed to a process of continuous development and technological improvement.

This has allowed ITW to achieve results that were believed to be technical unthinkable until now.

Using our expertise and our applied research capabilities, we can find innovative solutions to various problems affecting the oil and energy industries.

Contact us for any inquiry relating to improvement of process, production, environmental and turnaround issues.

An entire production unit can be cleaned in 24 hours.

A production Unit can be cleaned during the run without feed disruption

An entire production unit can be cleaned in 24 hours on a feed-out/feed-in basis.

A production Unit can be degassed/decontaminated in a 2-8 hours, by using ITW patented technology.

Downtime can be dramatically reduced by applying two unique and patented technologies.

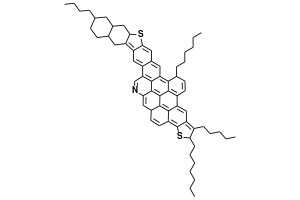

A polymer can be dissolved/modified by a patented chemical, such to allow equipment cleaning or polymer fouling prevention.

Ethylene furnace run length (Naphtha Cracker) can be increased by 70-100%.

Distillation yield in Delayed Coking Units can be increased by 4%

Reduction of coke formation on catalyst is possible by adding proprietary chemistries into the process.

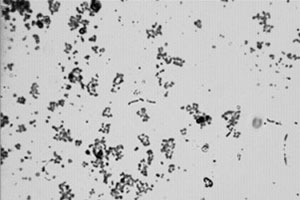

Sludge is fully and effectively recovered by using a closed loop, no man entry technology.

ITW can provide an Amine Full Management Approach, from prevention of HSS formation to Online Cleaning of HSS.

ITW can clean online Vertical exchangers (Texas Towers, VCFE, HCFE, etc.), Packinox or any feed/effluent exchanger.

ITW has a high specialization in the stabilization of asphaltenes and all related applications.

ITW technology can re-stabilize asphaltenes even after precipitation.

ITW performs chemical treatments of process and water.

ITW can improve combustion efficiency and reduce airborne emissions, both in power generation and automotive.

ITW can supply all the classic chemical cleaning services.

Particulate matter emission of diesel fuel can be reduced by > 70%.

ITW can implement research and develop tailor made solutions for Customers’ specific needs.